We’re known for delivering parts to customers that meet their exact requirements. In the competitive marketplace of manufacturing, our customers stay with us because we put their needs first in everything we do. This starts with starts with sales and customer service, but also extends to our investments in equipment, team development, and other proven means of continuous improvement.

Our Integrated Quality Management System is certified to ISO 9001/ IATF 16949. These process qualification standards enable us to meet stringent customer requirements for a wide range of industries and provide complete Production Part Approval Process (PPAP) for any part.

The use of both automated systems and human eyes to reliably deliver perfect parts. In addition, we use modern non-contact inspection systems and sophisticated statistical process control (SPC) software to record results. Finally, every part undergoes multiple visual inspections before being permitted to make its way to our customers.

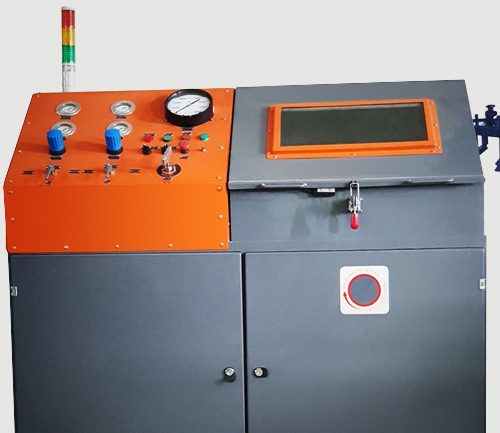

We are IATF 16949: 2016 Certified and follow all International Standards. Apart from testing our products in our world-class in-house testing facilities we also have independent testing partner Stork Laboratories, Iowa, USA for certifications.

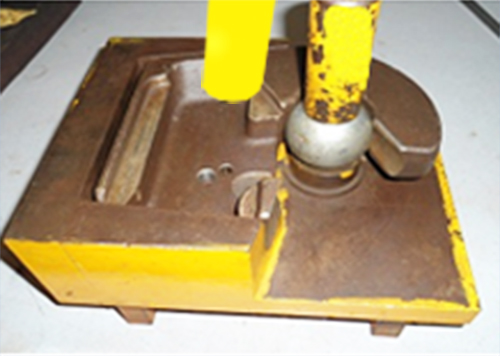

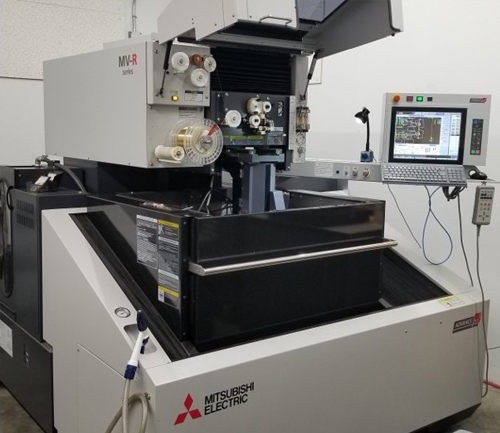

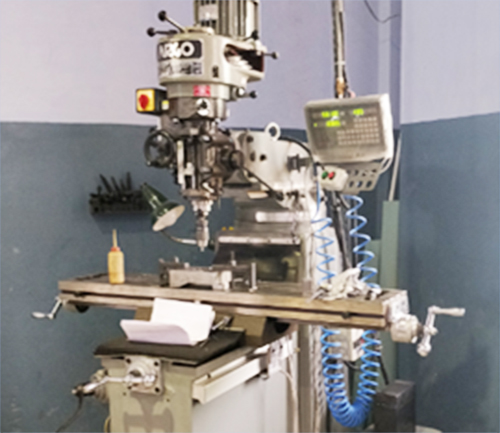

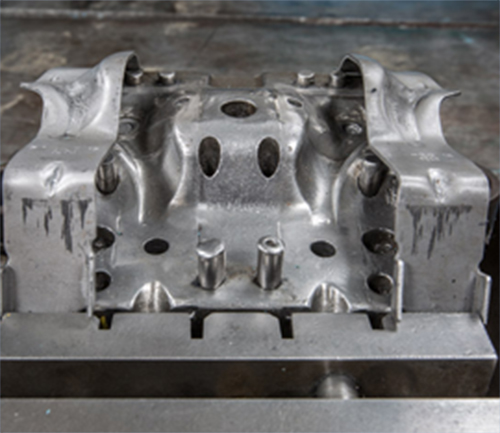

The High Quality Single Stage & Progressive Tools make King Group one of the best Hydraulic quick release coupler companies in India. The Product development process is supported by an in-house Tool Design team & Tool Manufacturing facility, monitored by a cross-functional APQP (Advance Product Quality Planning) team and also supported by FMEA/MSA/SPC activities.