Our engineers use AutoCAD to create highly accurate 2D and 3D drawings and schematics. This forms the foundation for concept development, layout planning, and tooling designs, ensuring every detail is precisely documented for manufacturing.

At King Group, our robust engineering and design capabilities are the backbone of our product development success. From initial concept to production-ready drawings, we blend creativity with technology to develop high-performance, cost-effective, and precision-engineered components for global industries.

We empower innovation through advanced design software, experienced engineers, and a commitment to quality at every stage of development. Whether you're launching a new product or optimizing an existing one, our engineering team ensures your design intent translates flawlessly into manufacturable reality.

Our engineers use AutoCAD to create highly accurate 2D and 3D drawings and schematics. This forms the foundation for concept development, layout planning, and tooling designs, ensuring every detail is precisely documented for manufacturing.

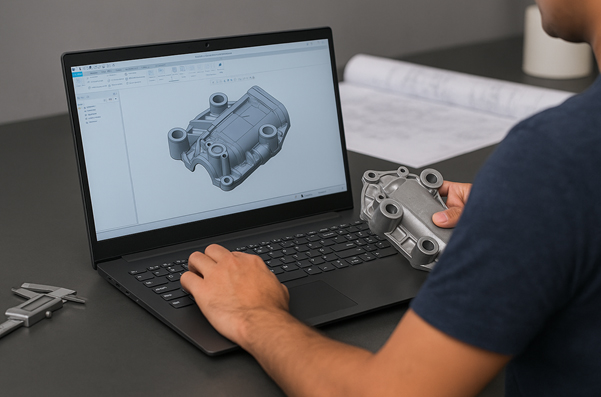

For detailed component modeling, SolidWorks is our go-to platform. From part and assembly modeling to simulation of motion and stress analysis, we use SolidWorks to design functional, real-world assemblies that reduce development cycles and improve product reliability.

Our team leverages PTC Creo (formerly Pro/ENGINEER) for advanced parametric design, allowing us to handle complex assemblies, surfacing, and geometric configurations. Creo’s robust features enhance our ability to execute intricate designs with consistent performance in demanding applications.

We offer reverse engineering services using 3D scanning and CAD reconstruction techniques to recreate existing parts. This is essential when legacy data is unavailable, and enables design enhancements, part validation, and rapid prototyping.

With a culture of continuous improvement and engineering excellence, King Group is your trusted design partner—bringing your ideas to life with technical precision and industry insight.