Forging Manufacturing Process

We follow a structured, quality-driven process to ensure your components are delivered with precision, durability, and compliance every step of the way.

We follow a structured, quality-driven process to ensure your components are delivered with precision, durability, and compliance every step of the way.

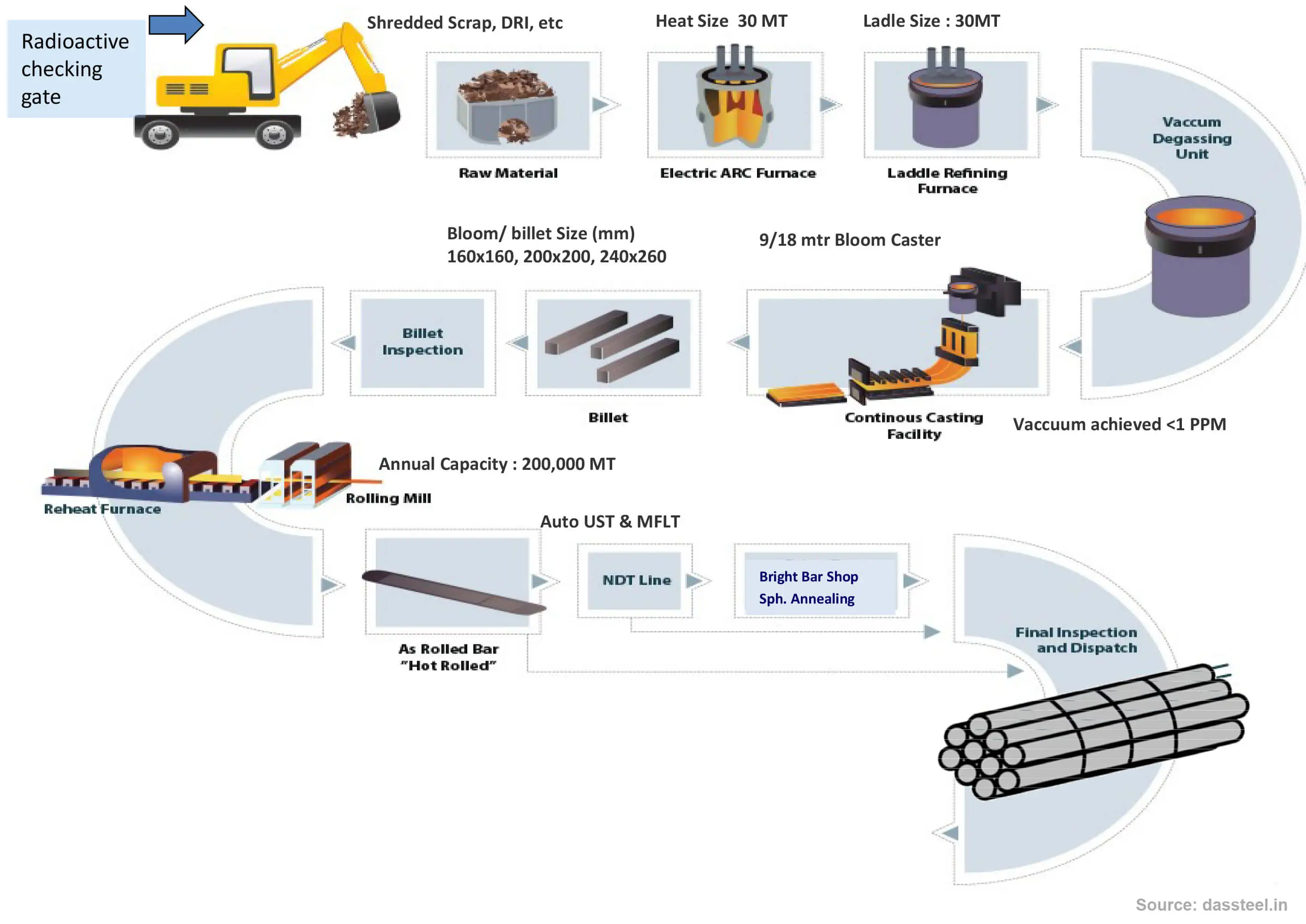

The foundation of any great product begins with the right raw material. We procure certified, high-grade materials based on your project’s specifications to ensure strength, reliability, and performance in the final component.

| Classification | IS | EN | DIN | AISI / SAE | JIS |

|---|---|---|---|---|---|

| Plain Carbon | 15C8, 35C8, 45C8 | EN-8, EN-9 EN-32 B | CK-15, CK-30, CK-45, C35 Pb K, C15 Pb K, CK-35, CK-60 | 1015, 1026, 1030, 1135, 1040, 1045, 1050, 1055, 1060, 1080 | S43C, S45C, S48C, S55C, S35C, S53C |

| Carbon Manganese | 47Mn6, 37Mn6, 37MN2, 37C15, 20Mn2 | EN-14A, EN-14B, EN-15, EN-15B | 40Mn4, 28Mn6, 27Mn2 | 1524, 1526, 1541, 1041F | SMn420H, SMn430H, SMn433H, SMn435H, SMn443H |

| Plain Chrome | 40Crl, 50Cr4 | EN-18, EN-207 | 34Cr4, 37Cr4, 41Cr4 | 5120, 5140, 5145, 5150, 5160 | SCr, 420H, SCr415 |

| Chrome Manganese | 16Mn5Cr4, 20Mn5Cr5 | - | 16MnCr5, 20Mn5Cr5 | - | - |

| Chrome Moly | 40Cr1Mo28 | EN-19 | 42CrMo4 | 4118, 4130, 4135, 4140, 4145, 4150, A182 F12 C1 II | SCM 415, SCM 420H, SCM 435H, SCM 440H |

| Chrome Nickel | 40CrNi6, 16Ni3Cr2 | EN-36A, EN-36B | 15CrNi6, 16CrNi4, 18CrNi8, 20CrNi4 | - | - |

| Chrome Nickel Moly | 20NiCr2Mo2 | EN-353, EN-354, EN-355, EN-36C, EN-24, 845H17, 822H17 | 17CrNiMo6, 30CrNiMo3, 34CrNiMo6 | 4340, 8620, 8640, 8627, 8615, 8617 | SNCM220H, SNCM420H |

| Moly-Manganese | 36Mn6Mo3, 35Mn6Mo4 | EN-16, EN-17 | - | 4027H, 4037H | - |

| Ball Bearing | 103Cr2 | EN-31 | 100Cr6 | SAE52100 | SUJ2 |

| Micro Alloyed | 38MnSiVS5 | - | - | - | - |

Once we receive your purchase order, we initiate a formal Design for Manufacturability (DFM) review with your team. This step ensures the part design is optimized for forging, reducing potential production issues and helping achieve better cost and time efficiency.

An optimized tool design is critical but often overlooked. By addressing DFM at this early stage, we help accelerate your go-to-market timeline and minimize rework or delays during production.

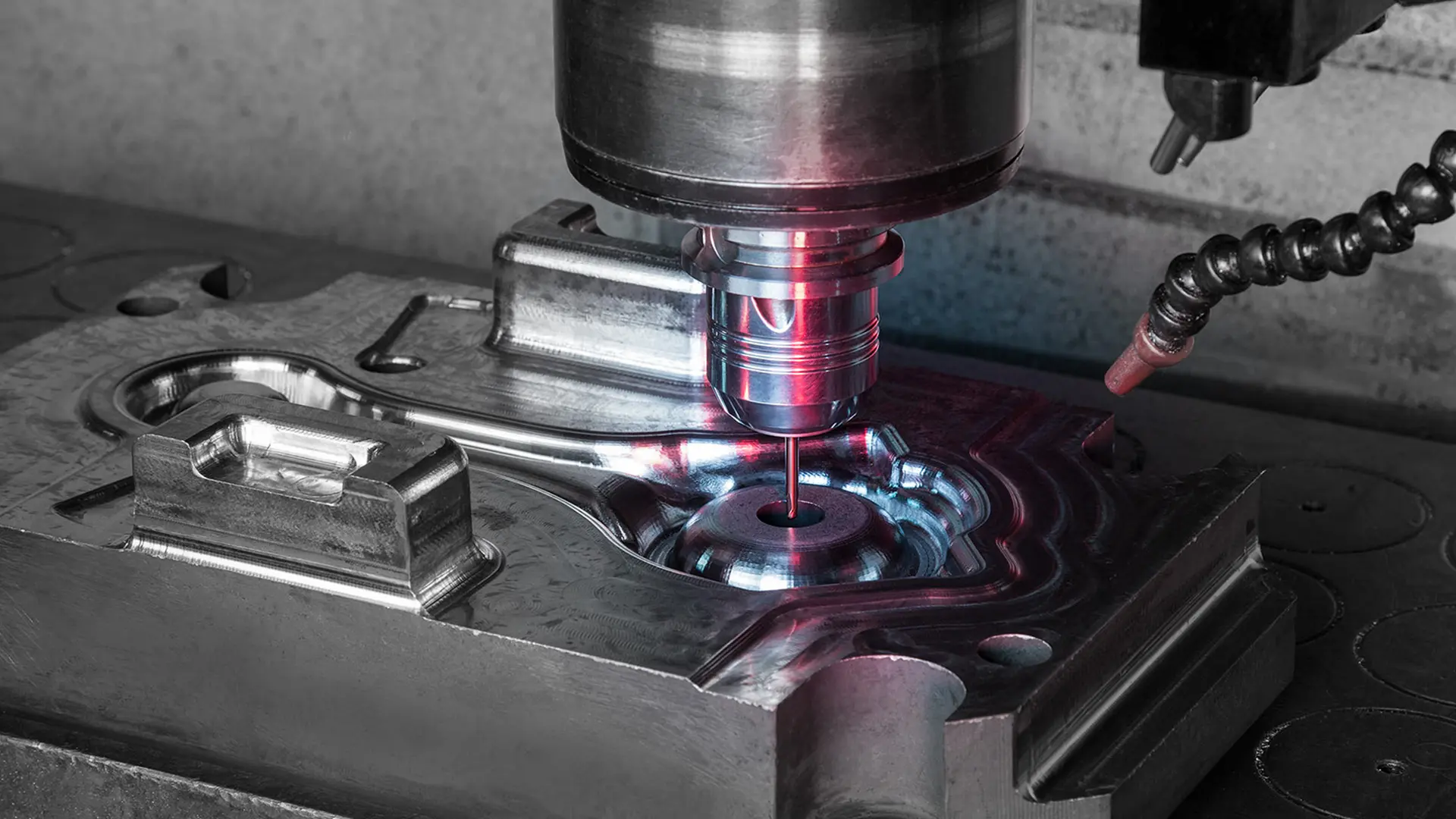

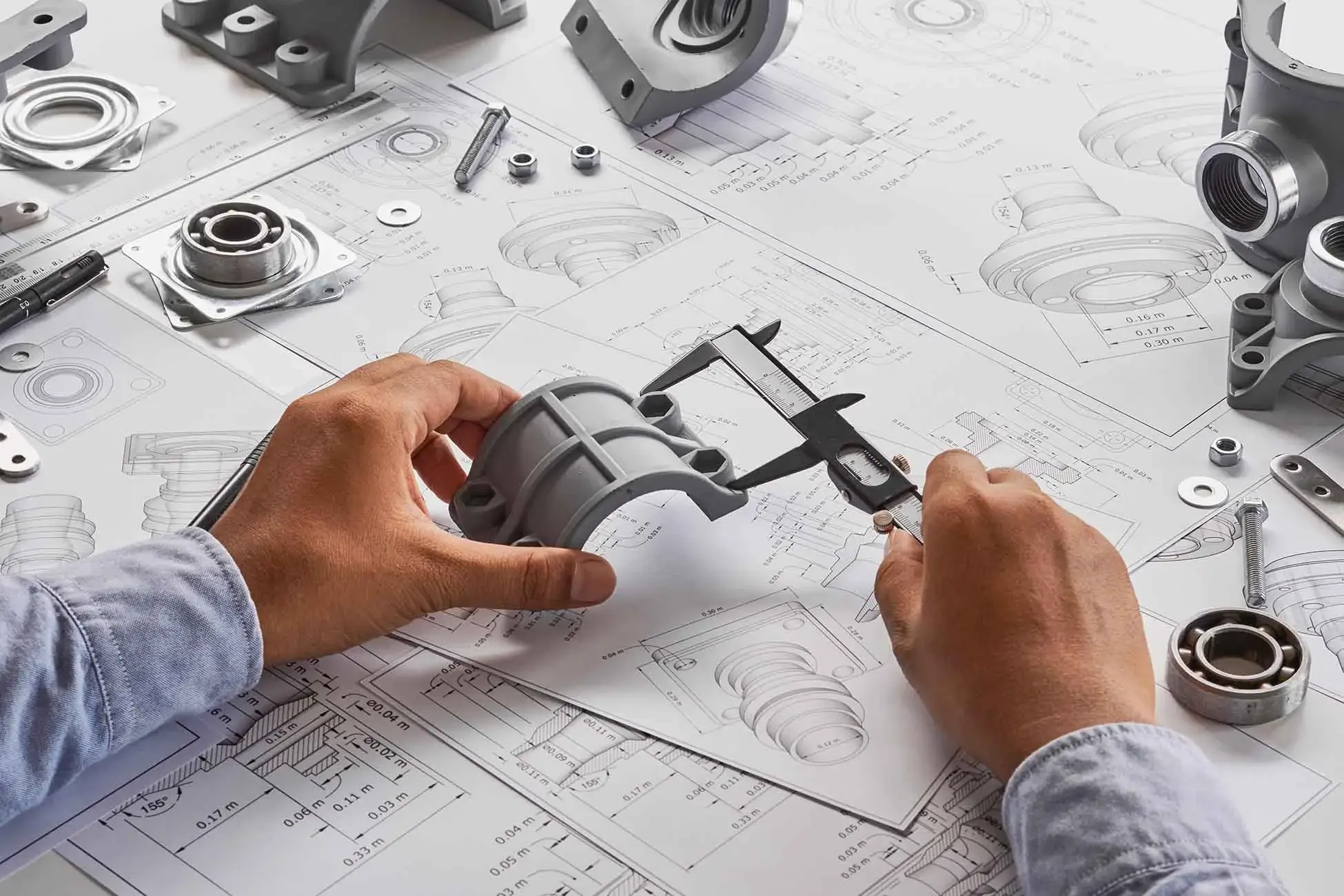

Our precision machining capabilities allow us to meet tight tolerances and deliver components that are ready for final assembly or integration. From turning and milling to drilling and boring, we handle every detail with accuracy and consistency.

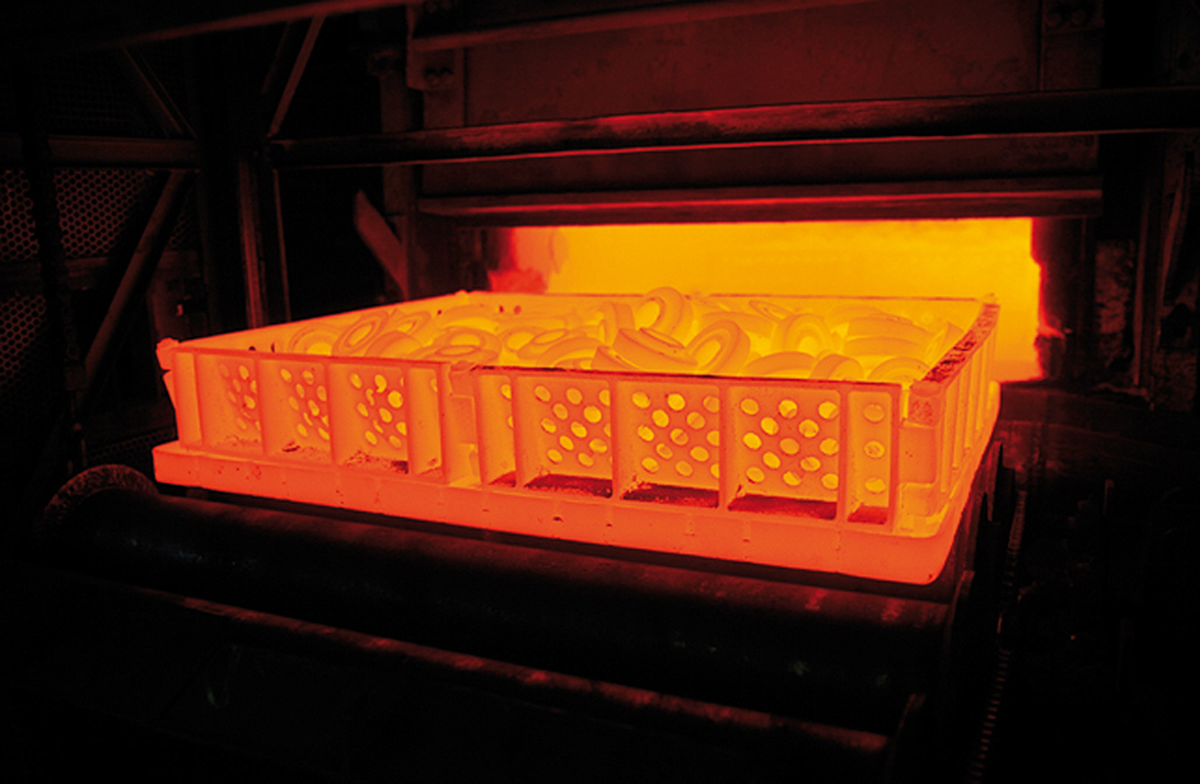

We apply various heat treatment and surface conditioning methods to enhance material properties like strength, ductility, wear resistance, and hardness. Our capabilities include:

Every component undergoes rigorous inspection and testing to ensure it meets your dimensional, mechanical, and material specifications. Our in-house capabilities include mechanical testing, dimensional inspection, NDT (Non-Destructive Testing), and welding quality validation.

We understand the importance of traceability and global quality standards. We provide complete documentation support, including:

Our team ensures you receive the necessary documentation for audits, certifications, and smooth project approvals.