Machining Capabilities & Services

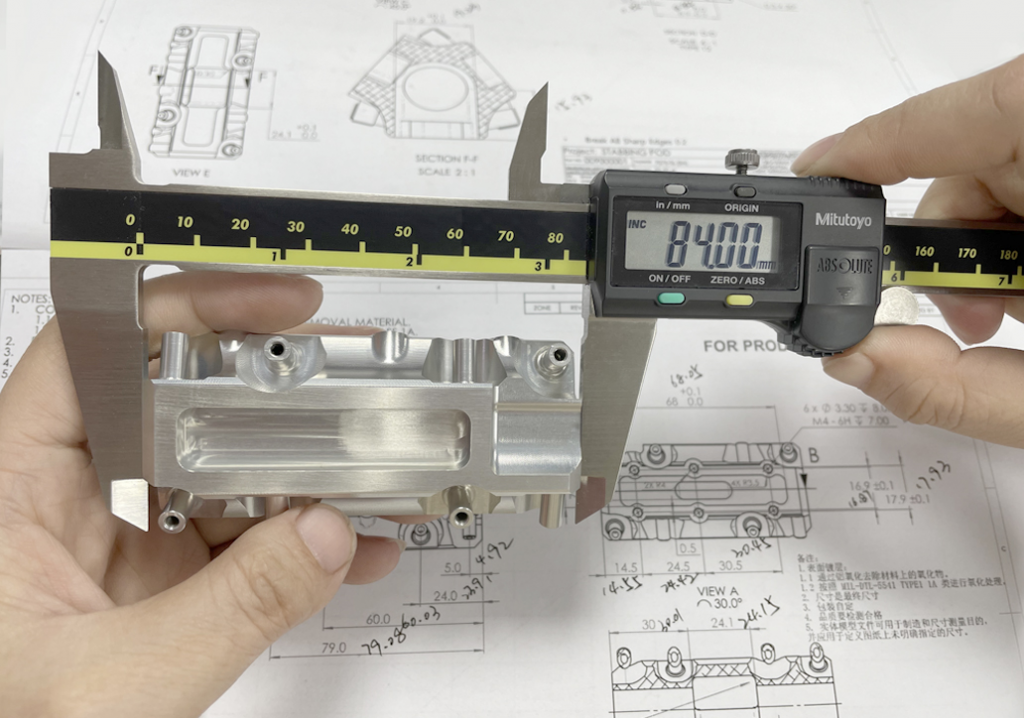

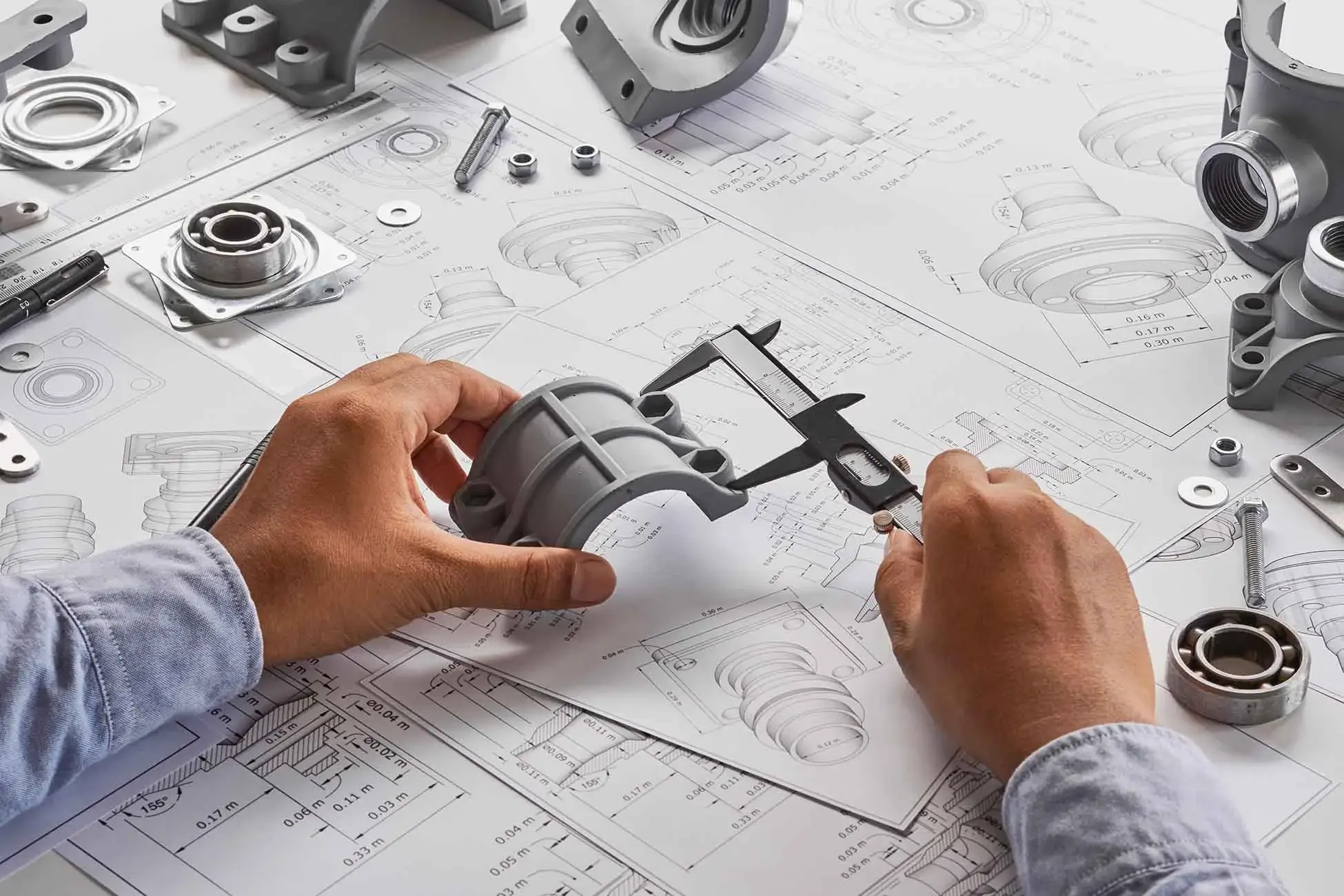

At King Group, we offer precision CNC and VMC machining services, supported by a highly skilled in-house engineering team and a robust infrastructure. Our facilities are equipped with 42 CNC machines and 15 VMC machines, enabling us to meet the demands of both complex geometries and high-volume production.

We specialize in machining components from bar stock, as-cast, and as-forged forms—delivering tight-tolerance, high-accuracy parts that meet the most demanding specifications. To provide a complete manufacturing solution, we also offer integrated heat treatment and surface finishing services, delivering fully finished, assembly-ready components from a single trusted source.