In the fiercely competitive landscape of manufacturing, our unwavering dedication to prioritizing our customers sets us apart. From the initial stages of sales and customer service to our unwavering commitment to investing in cutting-edge equipment, team development, and other well-established avenues of continuous improvement, we consistently place their needs at the forefront of everything we undertake.

Our Comprehensive Quality Management System holds the esteemed ISO 9001/IATF 16949 certification. These rigorous process qualification standards empower us to fulfil exacting customer demands across diverse industries while ensuring thorough Production Part Approval Process (PPAP) for every component.

We combine the power of automated systems and meticulous human oversight to consistently deliver flawless components. Furthermore, we employ advanced non-contact inspection systems and sophisticated statistical process control (SPC) software to meticulously document results. As an added layer of assurance, each part undergoes multiple visual inspections before being deemed ready for our esteemed customers.

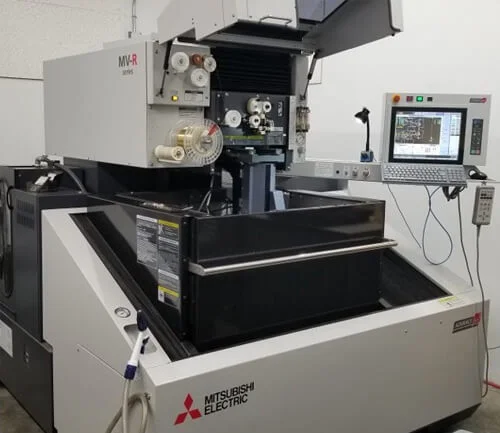

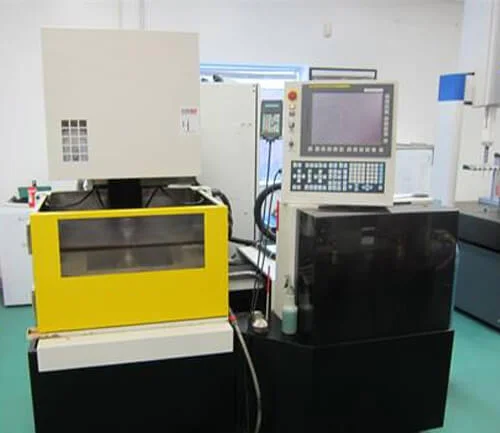

We possess exceptional in-house testing facilities of the highest calibre. Additionally, we collaborate with independent testing laboratories in India, USA, and Europe to obtain the necessary certifications. The following is an inventory of the equipment and machines employed in our operations:

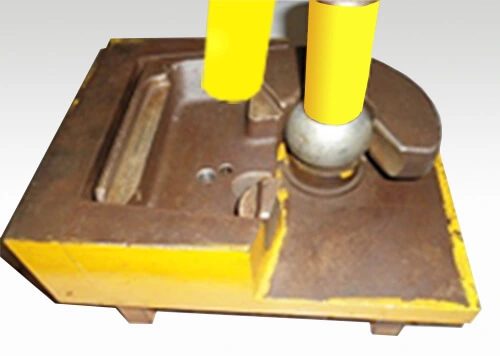

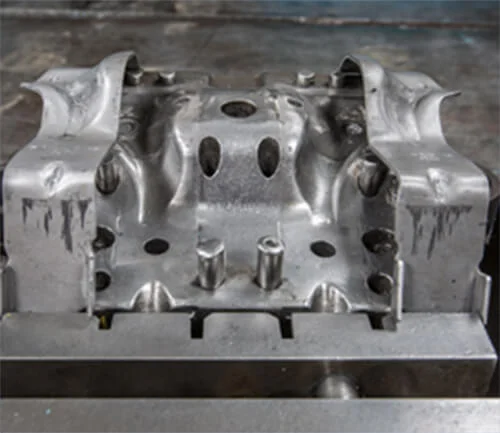

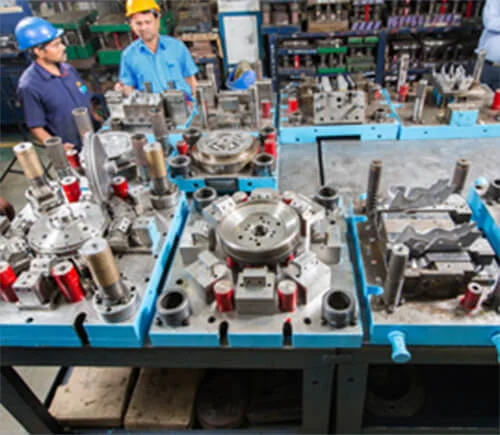

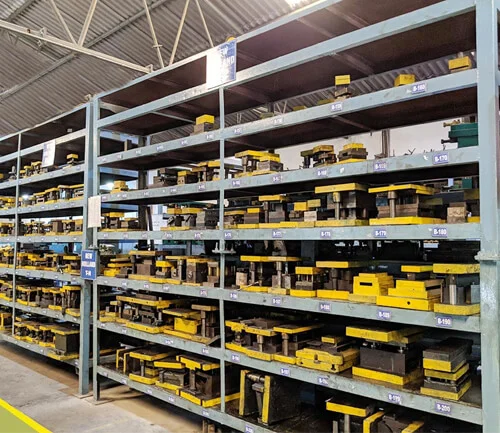

With the utilization of exceptional Single Stage and Progressive Tools of the utmost quality, King Group emerges as a preeminent entity in precision stamping, CNC machining, forging industries within India. Our product development process is fortified by an in-house team of experts specializing in Tool Design, bolstered further by our state-of-the-art Tool Manufacturing facility. This entire process is vigilantly overseen by a cross-functional Advance Product Quality Planning (APQP) team, supported by meticulous FMEA (Failure Mode and Effects Analysis), MSA (Measurement System Analysis), and SPC (Statistical Process Control) activities.