Stamping Shop – Precision Metal Forming by King

Group

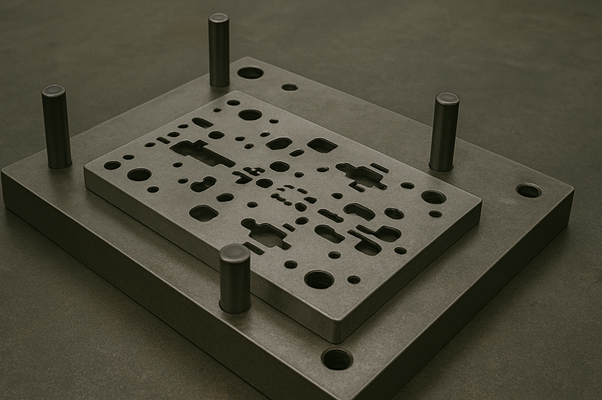

At King Group, our Stamping Shop is a powerhouse of precision engineering, designed to meet the

growing demands of high-volume and high-complexity metal forming. With over three decades of expertise and a

future-ready infrastructure, we are trusted by global OEMs and Tier-1 suppliers across sectors such as

automotive, agricultural equipment, construction hardware, general engineering, and heavy machinery.

Our facility is equipped with 30 mechanical presses and 20 high-speed de-coilers, enabling

consistent, scalable, and high-accuracy metal stamping for a wide range of parts and materials. Whether it’s a

simple bracket or a complex multi-stage part, we deliver results that exceed expectations in performance and

consistency.