Welding Capabilities & Services

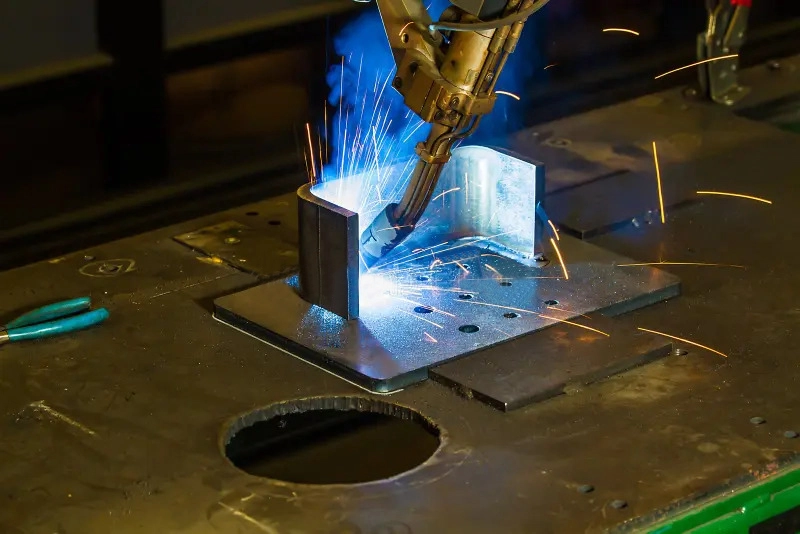

At King Group, we deliver high-precision welding services tailored to global quality standards, backed by certified welding engineers (TÜV) and advanced robotic welding systems. Our processes adhere to internationally recognized standards such as DIN 18800-7 and AWS D1.1, ensuring structural integrity and consistency across every weld.

We work with a wide range of materials including carbon steel, alloy steel, stainless steel, and aluminium, utilizing Gas, MIG, TIG, Spot and Arc welding techniques based on project requirements. Our automated welding systems support wire sizes ranging from 0.82mm (0.032”) to 1.4mm (0.055”), enabling repeatable, high-strength welds across varied part geometries.

Whether for high-volume production or specialized applications, our welding division ensures every component meets stringent mechanical and aesthetic requirements—providing fully welded, inspection-ready parts from a single, reliable source.