King Group stands as the premier choice for contract manufacturing of Stamped, CNC machined, Forged, Welded, Thread rolled components & specializing in precision metal forming. With a remarkable track record spanning three decades, we have successfully produced over 35,000 unique parts for esteemed global companies, serving a wide array of industries. We offer effective solutions to address your outsourcing and vendor reduction challenges through our comprehensive in-house production capabilities, supported by state-of-the-art machinery detailed below.

Engineering/Design Capabilities

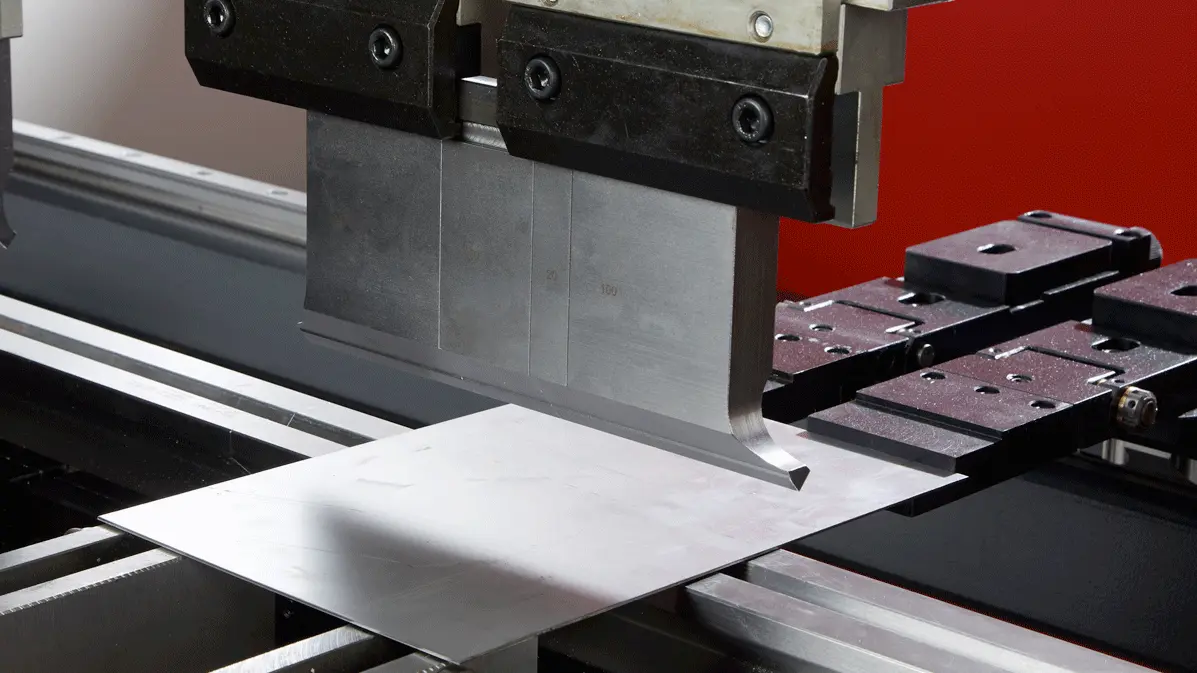

Fabrication

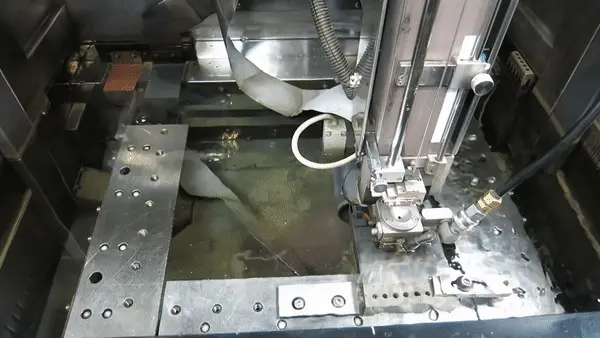

VMC Machining (12 No.)

VMC Machining (12 No.)

- Carbon, Alloy, Stainless Steel & Aluminium

- Bed Size : 600mm (23.62”) x 400mm (15.75”) x 400mm (15.75”)

CNC Machining (42 No.)

CNC Machining (42 No.)

- Carbon, Alloy, Stainless Steel & Aluminium

- Range: Dia. upto 200mm (7.87”) Length upto 500mm (19.69”)

Drop Forging (1 Ton to 5 Ton)

Drop Forging (1 Ton to 5 Ton)

- Carbon, Alloy & Stainless steel

- Range: 0.2Kg. (0.44 lbs) to 5Kg (11.02 lbs)

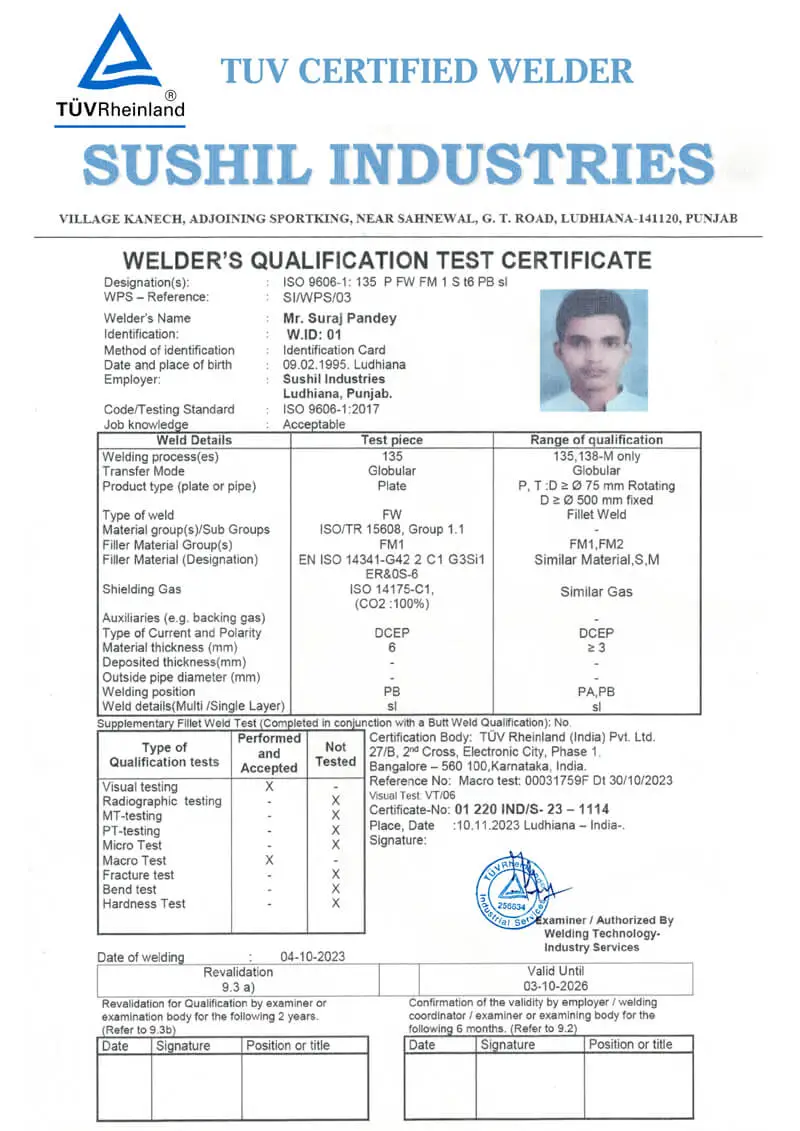

Welding (35 No.)

Welding (35 No.)

- As per Standard DIN18800-7 or AWS D1.1

- Using wire from 0.82mm (0.032”) to 1.4mm (0.055”)

- Robotic Weldings

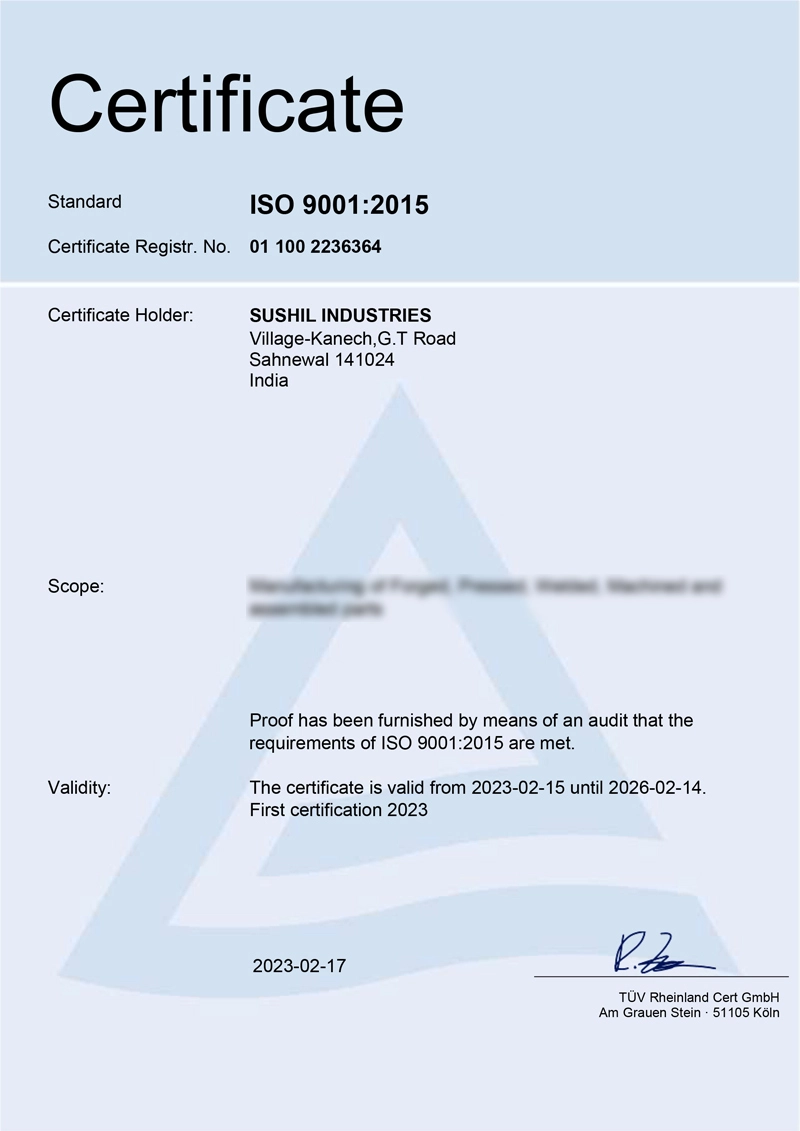

- Certified Welding Engineers by TUV

- Carbon, Alloy, Stainless Steel & Aluminium

- Gas, MIG, Arc & TIG Welding.

Stamping Shop

Stamping Shop

- Mechanical Presses (30No., Capacity upto 250 Tons)

- De-coilers (20No.)

- Shapes - Rounds, Spines, Tangs, and ears to no limitations.

- Progressive Die Stamping

- Carbon, Alloy, Stainless Steel & Aluminium

- Range: Bed sizes upto 275 mm (10.83”) x 300 mm (11.81”)

Supporting Process

Drilling Machines (20 No.)

Drilling Machines (20 No.)

- Carbon, Alloy, Stainless Steel & Aluminium

- Range: 3 mm (0.12”) to 40 mm (1.57”)

Clean Room Assembly

Clean Room Assembly

- All our hydraulic components are assembled in a clean room environment to meet ISO 19/17/14 cleanliness standards.

Surface Treatment

Treatment

Treatment

- Hardening & Tempering

- Annealing

- Normalizing

- Forced Draught

- Bottom Drop Hardening

- Gas Carburizing

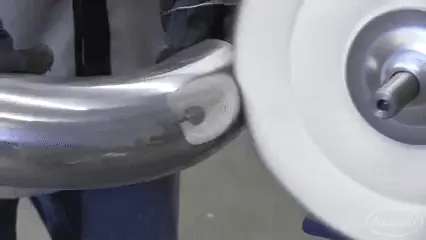

Finishing

Finishing

- Powder Coating Shop

- Paint Coating Shop

- Electro Plating

- Passivated Coating (Trivalent, Hexavalent)

- Hot Dip Galvanization (ASTM 123)

- Stainless Steel Shot Blasting

- Stainless Steel Electro Polishing

- Anodizing

Packaging

Packaging

Packaging

- Universal Pallets

- Card Board Cartons

- PPE Bags

- Fumigation Pallets (as per ISPM 15)

- Litho Cartons

- Bar Coding

- Label Scanning

- Full Range of Graphics

- Laser Engraving

- Customised Packing

- Gift Box Packaging

Quality control

In-house Testing Facilities

In-house Testing Facilities

- Wet Analysis

- Astro Helien Apparatus

- Hot Plate

- Muffle Furnace

- Universal Testing Machine

- Brinal Hardness Tester

- Rockwell Hardness Tester

- Burst Test Machine

- Profile Projector

- Magnetic Particle Inspection

- Hydraulic Test

- Salt Spray Test

Tool Room Facilities

Tool Room Facilities

Tool Room Facilities

- In house Manufacturing of SPM’s

- In house Manufacturing of Gauges

- In house Manufacturing of Special Tools

- In-house Tool Design team & Tool Manufacturing facility

- Monitored by a cross-functional APQP team

- Supported by FMEA/MSA/SPC activities

NPD/Reverse Engineering

NPD/Reverse Engineering

NPD/Reverse Engineering

- Improve product functionality

- Product development based on samples

- Create new CAD models